Best Practices to Ensure OSHA-Compliance for Power Lift Equipment

Warehouse operations are designed to optimize efficiency, and power-lift equipment such as forklifts, pallet jacks, and scissor lifts plays an essential role in ensuring smooth operations. However, improper use of power-lift equipment can lead to accidents, injuries, or even fatalities, making it a key focus of OSHA regulations.

Beyond regulatory compliance, prioritizing the safety of warehouse and power-lift equipment is also a smart business move. When warehouses establish clear standards, train operators effectively, and use the right tools, they protect both their people and their bottom line.

These best practices can help warehouse operations teams align with OSHA expectations for power-lift equipment and create safer, smoother-operating warehouses that comply with OSHA safety regulations.

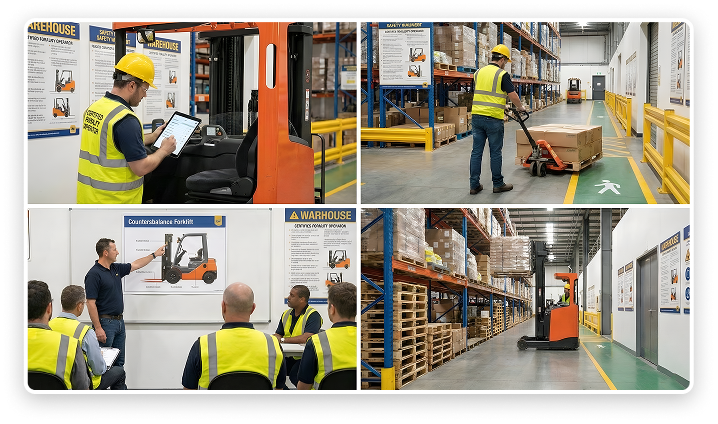

Enforce Operator Training & Evaluation

- Provide formal instruction, practical training, and evaluation before allowing workers to operate powered industrial trucks, in accordance with 29 CFR 1910.178. (osha.gov)

- Re-evaluate operators periodically and whenever there’s an incident, near miss, or change in equipment or environment.

- Ensure that only operators certified for power lift equipment are involved in operating the equipment.

Create & Maintain Written Policies, Procedures, and Signage

- Maintain written forklift and lift-equipment safety rules that reflect OSHA standards and site-specific hazards.

- Clearly post speed limits, load ratings, and traffic patterns throughout the warehouse, in line with OSHA’s guidance for warehousing and material handling. (osha.gov)

Conduct & Document Equipment Inspection & Maintenance

- Require pre-shift inspections of powered industrial trucks and keep records of issues found, repairs, and preventive maintenance activities, as recommended under OSHA’s powered industrial truck standard. (osha.gov)

PPE Hazard Assessment & Provision

- Conduct a documented PPE hazard assessment and ensure appropriate PPE (e.g., safety footwear, high-visibility garments, eye and head protection) is provided, used, and maintained in a safe condition, as required in 1910.132. (osha.gov)

Perform Ongoing Safety Audits & Document Corrective Actions

- Perform routine safety audits of lift-equipment operations and warehouse traffic flow using OSHA’s warehousing checklists and resources. (osha.gov)

- Track incidents and near misses, then feed those learnings back into training, procedures, and digital inspection workflows.

Linking daily safety practices to OSHA standards helps warehouse leaders move beyond basic compliance to a proactive safety culture where risks are identified early and consistently addressed.

The Role of Employers in Promoting Warehouse Equipment Safety

Employers play a central role under OSHA in ensuring the safety of warehouse power-lift equipment. OSHA requires employers to establish and enforce safe operating practices and protect workers from preventable hazards. While every operator is responsible for how they drive and operate equipment, warehouse management sets the tone for safety and needs to provide the infrastructure and resources to ensure safe operations. Employers should:

- Invest in high-quality equipment and PPE that meets or exceeds regulatory requirements.

- Provide comprehensive training (classroom + hands-on) before allowing anyone to operate a lift, and keep detailed training and evaluation records.

- Make safety expectations visible and specific—through policies, signage, and daily conversations.

- Encourage hazard and near-miss reporting without blame, so problems surface early.

- Use OSHA resources and internal audits to continuously improve safety practices.

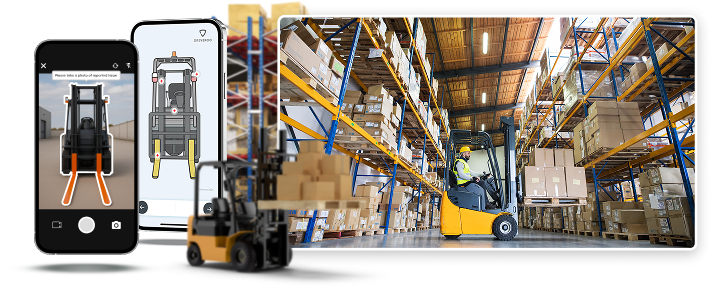

Many warehouse operators are modernizing their efforts with digital tools like Driveroo and ROO.AI. A visual, mobile workflow platform can:

- Walk operators through OSHA-aligned pre-operation and site safety inspections step by step.

- Capture photo and video evidence of equipment condition with time, location and date tracking.

- Schedule regular maintenance and trigger automated repair requests when issues are found.

- Simplify incident and hazard reporting to make information immediately available to supervisors and EHS teams.

- Automate the assembly of OSHA safety compliance documentation and ensure easy reporting and auditability

While essential, operating power lift equipment in a warehouse is a high-stakes responsibility that demands training, vigilance, and consistent adherence to safety standards. By combining OSHA-compliant practices with modern digital tools and strong leadership commitment, warehouses can significantly reduce risks—protecting workers, minimizing downtime, and building a safer, more productive operation for everyone involved.

OSHA Compliance for Lift Equipment Safety Resources

For U.S. operations, compliance with OSHA (Occupational Safety and Health Administration) regulations is central to the safe use of lift equipment. OSHA’s standards for warehousing and powered industrial trucks set clear expectations for training, inspections, and safe operation.

Key OSHA references for lift equipment and warehouse operations include:

- Powered Industrial Trucks (Forklifts) Overview – OSHA’s primary hub for forklift safety requirements and best practices for powered industrial trucks (PITs). (osha.gov)

- OSHA Standard 29 CFR 1910.178 – Powered Industrial Trucks – Details requirements for design, maintenance, training, and operation of forklifts and similar equipment. (osha.gov)

- Warehousing – OSHA Safety and Health Topic Page – Provides an overview of warehouse hazards and links to relevant standards and resources. (osha.gov)

- Warehousing: Hazards and Solutions – Offers practical guidance on common risks (including forklifts, material handling, and pedestrian safety) and how to reduce them. (osha.gov)

- OSHA Standard 29 CFR 1910.132 – General Requirements for PPE – Defines employer responsibilities for assessing hazards and providing appropriate personal protective equipment. (osha.gov)

FAQ: OSHA & Power Lift Equipment Safety in Warehouses

Q1: What OSHA standards apply to forklifts and other power lift equipment?

OSHA regulates forklifts and most powered industrial trucks under 29 CFR 1910.178 – Powered Industrial Trucks. This standard covers operator training, equipment operation, maintenance, and workplace conditions. Depending on your environment, other general industry standards may also apply, such as walking-working surfaces, hazard communication, and PPE requirements.

Q2: How often does OSHA require forklift operator training and recertification?

OSHA requires that operators receive initial training and evaluation before operating powered industrial trucks independently. After that, employers must:

- Re-evaluate each operator at least once every three years.

- Provide refresher training whenever an operator is observed operating unsafely, is involved in an accident or near miss, or when there are changes in equipment, loads, or the operating environment.

Q3: Does OSHA require daily inspections of powered industrial trucks?

Yes. OSHA expects pre-use inspections at least once per shift for powered industrial trucks. These inspections should check critical safety components such as brakes, steering, tires, hydraulics, forks, controls, and safety devices. Any unsafe condition must be corrected before the equipment is returned to service, and it should be tagged “Out of Service” until repaired.

Q4: What are OSHA’s expectations for PPE in warehouse environments?

OSHA requires employers to conduct a hazard assessment and determine necessary PPE under 29 CFR 1910.132. In a warehouse with lift equipment, this often includes:

- Safety-toe footwear

- High-visibility vests or garments

- Hard hats or bump caps

- Gloves suitable for materials handled

- Eye and face protection where needed

Employers must provide PPE (when required), train workers on its use and limitations, and ensure it is maintained in a safe, sanitary condition.

Q5: What are the most common OSHA violations related to lift equipment?

Frequent issues include:

- Allowing untrained or uncertified employees to operate forklifts

- Missing or incomplete pre-shift inspection records

- Operating defective equipment that should be out of service

- Exceeding rated load capacities or lifting unstable loads

- Poor traffic management, such as unmarked pedestrian zones or congested aisles

Addressing these areas with clear procedures, training, and digital checklists significantly reduces risk and the likelihood of violations.

Q6: How can digital inspection tools support OSHA compliance?

Digital tools like Driveroo and ROO.AI help align daily operations with OSHA expectations by:

- Standardizing and timestamping pre-operation inspection checklists

- Capturing photo and video evidence of equipment condition

- Automatically flagging unsafe issues and generating maintenance work orders

- Storing inspection and maintenance data in one place for easy audit and investigation

- Embedding safety instructions and reminders directly into the operator’s workflow

This improves consistency, makes compliance easier to prove, and helps identify trends before they become incidents.

Q7: What should be included in a warehouse’s OSHA-aligned lift equipment safety program?

A strong program typically includes:

- Written policies based on OSHA standards and site-specific risks

- Formal operator training, evaluations, and documented recertifications

- Pre-shift inspections and a preventive maintenance schedule

- Clearly marked traffic routes, speed limits, and pedestrian walkways

- PPE requirements and enforcement

- Incident and near-miss reporting and investigation

- Regular audits, corrective actions, and continuous improvement

Q8: Are supervisors personally responsible for ensuring OSHA compliance in their areas?

While ultimate responsibility lies with the employer, supervisors are typically accountable for enforcing safety rules day to day. That includes verifying only trained operators use equipment, ensuring inspections are completed, addressing unsafe behaviors immediately, and escalating hazards or equipment issues. Strong leadership engagement is one of the most important drivers of an OSHA-compliant safety culture.