Making Sure Your Forklift Pre-Operation Inspections Meet OSHA Standards

Forklifts are essential to warehouse, manufacturing, and distribution operations—but they’re also one of the most common sources of serious workplace injuries. According to the Occupational Safety and Health Administration (OSHA), approximately 200 forklift incidents occur every working day in the US. Accordingly, OSHA requires that powered industrial trucks be inspected before being placed into service to ensure safe operation, and failure to do so is a frequent cause for citation during safety audits.

Meeting OSHA requirements for forklift pre-operation inspections isn’t complicated, but it does require a focus on three key elements: consistency, documentation, and operator accountability. Embedding this focus into your inspections will help ensure your safety processes are compliant, effective, and actually improve safety—not just checking a box.

Understanding What OSHA Requires for Forklift Inspections

OSHA standard 29 CFR 1910.178(q)(7) states that industrial trucks must be examined before being placed in service, and must not be operated if found to be unsafe. In practice, this means:

- Inspections are required at least once per shift

- Defects must be reported immediately

- Unsafe forklifts must be removed from service until repaired

What Should Be Checked During a Pre-Operation Inspection

OSHA does not mandate a specific checklist format, but it does expect inspections to cover critical safety components and to be performed consistently. A compliant forklift pre-operation inspection should cover both equipment condition and operator readiness.

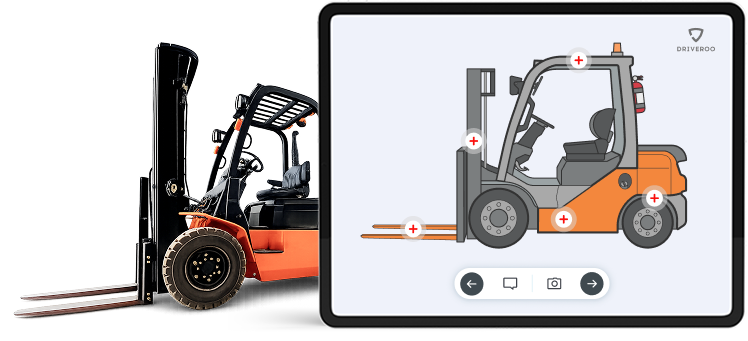

Visual Equipment Checks

- Forks (cracks, bends, wear)

- Mast, chains, and rollers

- Overhead guard

- Tires (condition and inflation)

- Hydraulic, oil, or fuel leaks

Operational Checks

- Service and parking brakes

- Steering

- Horn and warning devices

- Lights and backup alarms

- Lift, tilt, and side-shift functions

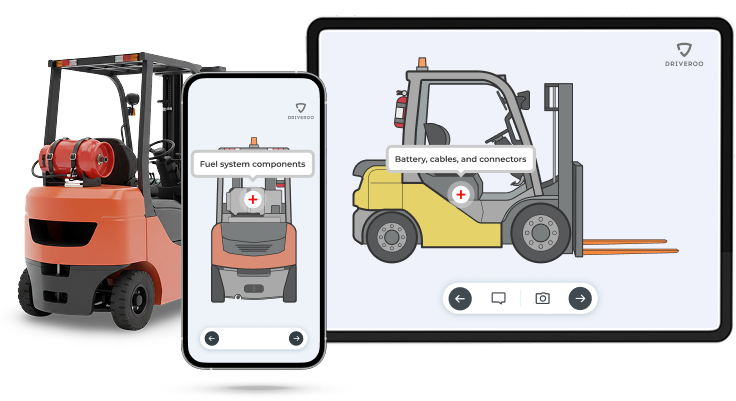

Power Source Checks

- Fuel system components on internal combustion forklifts

- Battery condition, cables, and connectors on electric forklifts

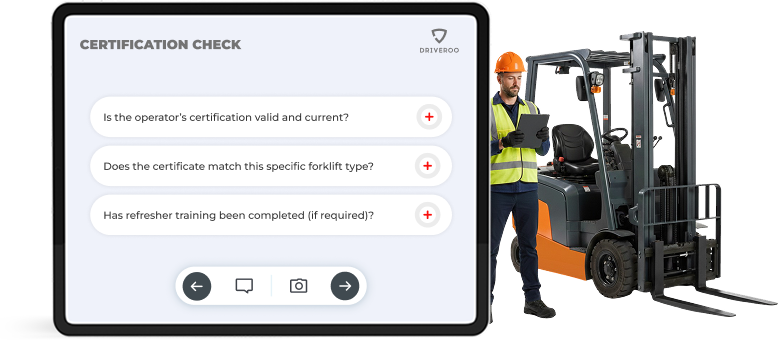

Operator Certification Check

OSHA also requires that only trained and certified operators operate forklifts. As part of the pre-operation process, organizations should verify that:

- The operator is currently certified

- Certification is appropriate for the specific forklift type

- Refresher training has been completed when required

Allowing uncertified operators to use a forklift is a serious OSHA violation, regardless of how well the equipment itself is inspected.

Training Operators to Inspect Correctly

Forklift inspections are only as good as the people performing them. OSHA expects operators to be trained not only in driving but also in recognizing unsafe conditions. It is important for management and floor supervisors to ensure forklift operators understand which items need inspection and how to inspect each item properly. Operators should know how to recognize safety issues, damage or excessive wear that could lead to problems. The process for capturing and communicating issues and taking steps to remove an unsafe or damaged forklift from operation should be well understood and easy to execute.

Short refresher training sessions, visual inspection guides, and standardized checklists help reinforce proficiency and reduce guesswork—especially for new or infrequent operators.

The Importance of Consistency and Accuracy

One of the most common reasons forklift inspection programs fail is inconsistency. If inspections vary by operator, shift, or location, hazards can easily be missed. Managers and supervisors on the shop floor should take special note of some common inspection breakdowns that are major sources of inconsistency, including:

- Rushing through inspections at the start of a shift

- Skipping inspection days entirely

- “Pencil whipping” checklists without actually checking equipment

- Different operators inspecting different items – non-standard inspection

OSHA expects inspections to be repeatable and reliable. A strong inspection process ensures that every forklift is checked the same way.

Documentation Is The Best Proof of Compliance

While OSHA does not explicitly require written inspection records in every case, documentation is often what determines whether you pass or fail an audit or investigation. Without documentation, it becomes difficult to prove that inspections were completed before use, even if they were. To ensure that you have effective proof of inspection, individual checklists or records should always include the date and time of the inspection, who was doing the inspection and on what piece of equipment. It is also important to document the inspection results and identification of issues. Along with issues, a record of corrective actions and repairs is important for demonstrating attention to workplace safety.

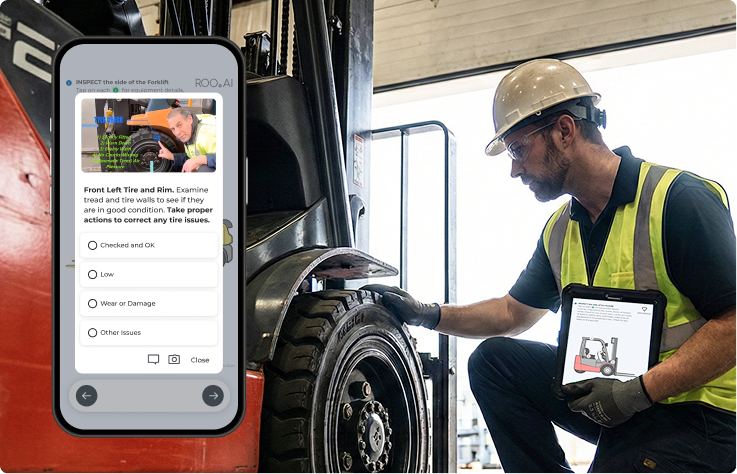

Strengthening Compliance with Digital Inspections

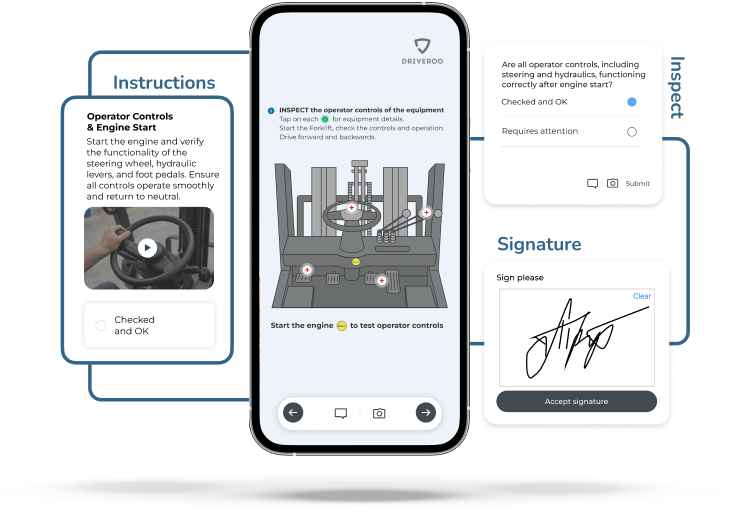

Many organizations are replacing paper checklists with digital inspection tools to reduce errors and improve visibility. Digital inspections help support OSHA compliance by:

- Requiring completion of all inspection steps

- Capturing photos or notes for defects

- Time-stamping inspections automatically

- Storing inspection records securely

- Making it easier to review records for audit purposes

Additionally, smart inspection platforms like Driveroo incorporate visual guidance and training to help new operators onboard more quickly and ensure inspections are conducted properly every time. Instant visibility into issues enables safety and maintenance personnel to respond faster and ensure forklifts are safe and operating as quickly as possible. Alerts for missed inspections help supervisors manage compliance and hold operators accountable. While digital tools aren’t required by OSHA, they significantly reduce the risk of missed or sloppy inspections and incomplete records, while helping to streamline operations.

Making Operations Work Better and Safer

Forklift pre-operation inspections are one of the simplest and most effective ways to prevent injuries, equipment damage, and OSHA citations. By ensuring operators are certified, training them to inspect properly, enforcing consistency, and maintaining clear documentation, you build a process that protects both your people and your operation.

OSHA compliance for forklift inspections isn’t about paperwork—it’s about making sure every forklift is safe and functioning properly before it’s put to work. In turn, that boosts operational efficiency and operator productivity, a result that every business can appreciate.